School leavers can now do an apprenticeship in 3D printing

- Emma Finamore

- 11 Apr 2018

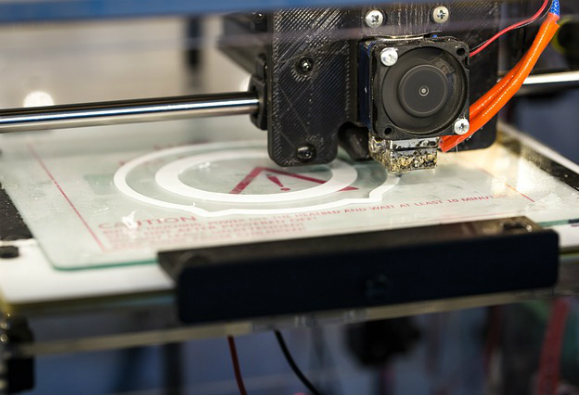

3D printing enables people to produce everything from parts for air and spacecraft, as well as prosthetic limbs, skateboards, entire cars and even houses.

The first 3D printing apprenticeship is launching, ensuring the UK has the skills needed for one of the fastest growing technologies in the manufacturing industry.

The Manufacturing Technology Centre (MTC) in Coventry is launching the programme, via which trainees will learn about the process of printing three dimensional, solid objects from just a digital file.

The creation of a 3D printed object is achieved using additive processes, by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced horizontal cross-section of the eventual object.

3D printing – otherwise known as additive manufacturing – enables people to produce complex and functional shapes using less material than traditional manufacturing methods. Parts for air and spacecraft can be constructed using this method, as well as everything from prosthetic limbs and skateboards to entire cars and even houses.

The MTC houses the National Centre for Additive Manufacturing (NCAM) bringing together the most comprehensive combination of equipment and capability in the UK.

The MTC's learning design manager Martin Dury said the new apprenticeship programmes are to be launched in September this year and will address the current shortage of skills in this vital area of advanced manufacturing.

3D printing – otherwise known as additive manufacturing – enables people to produce complex and functional shapes using less material than traditional manufacturing methods. Parts for air and spacecraft can be constructed using this method, as well as everything from prosthetic limbs and skateboards to entire cars and even houses.

"While there are a number of additive training courses currently available in the UK, these tend to be focused on equipment use. The MTC is aiming to provide3D printing apprenticeships that will cover the whole range of competences necessary for specific occupations. They will also offer accredited curricula of short courses to enable the up-skilling of existing staff.

"We are currently writing competency frameworks that will define the knowledge, skills and behaviour required to operate in the various job roles in an end-to-end additive manufacturing production environment. These frameworks will then form the foundation for the apprenticeship programmes and short course curricula. We have spent the last three months consulting with industry, manufacturers, OEMs and academia to ensure the frameworks exactly match the needs of industry."

He added: "The Manufacturing Technology Centre is an acknowledged world leader in additive technology and the home of the National Centre for Additive Manufacturing. We have all the equipment and capabilities to deliver first class, sector-wide and technology agnostic programmes for apprentices or existing employees.

The manufacturing industry is crying out for this and we will be able to make it available in a format which allows people to learn while earning, funded by the Apprenticeship Levy."

News

- GCSE results 2016: teenagers face an ‘information overload’ when it comes to career choices, says new report

- Fund launched to help young people facing enterprise postcode lottery

- The benefits system might be stopping people doing apprenticeships

- UCAS reports record number of people placed in their first choice university

- Where are all the female entrepreneurs?

- The School Leaver Awards 2019 finalists announced

- The top 10 cities for career prospects

- Britain drops down university global rankings for employability

- A fifth of young people fear apprenticeships will leave them trapped in an industry for life

- New management Degree Apprenticeships set to launch